Waste of all kinds has become a pressing issue in today’s modern world. One of the most prevalent forms of waste we see on a daily basis is packaging waste: often from food, drinks, or other perishables.

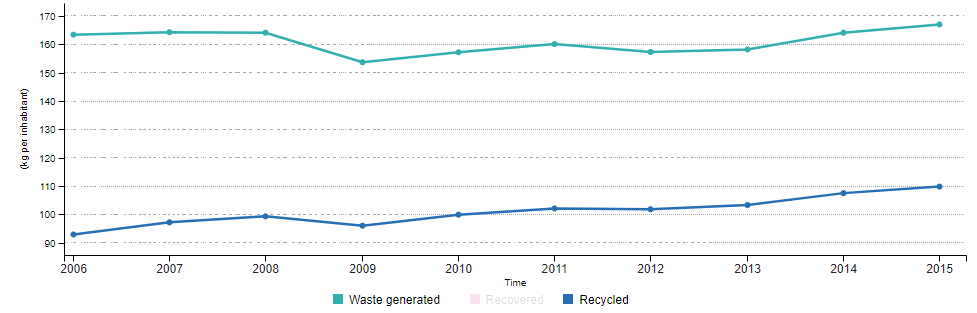

The amount of packaging waste created has been steadily increasing and the EU is currently at the staggering yearly per capita rate of 167 kg [6].

Share of recycled packaging material (Source: EUROSTAT )

Two common forms of packaging waste are plastics, which make up 19% of the total waste, and metals (largely tinplate and aluminum) that make up 5% of the total [1].

Two common forms of packaging waste are plastics, which make up 19% of the total waste, and metals (largely tinplate and aluminum) that make up 5% of the total [1].

When comparing packaging waste from plastics and metals it is necessary to analyze each from cradle to grave. Both plastics and metals can have negative effects on the environment, but when an in-depth review of both is conducted it becomes clear which is the more sustainable choice.

Environmental Impacts Caused by Packaging Production

Plastics used in packaging are commonly types of polyethylene, like Polyethylene Tetraphalate (PET) and High Density Polyethylene (HDPE). They are produced from petroleum in an energy intensive process known as polymerization. Polymerization is the joining of many small molecules into large chains of molecules.

Petroleum is directly used to make plastic and as a fossil fuel to power the production process. Fossil fuels release greenhouse gasses that cause climate change. Additionally, petroleum is a limited resource that scientists have predicted will be largely gone within the next few hundred years. Even though plastic production has some very negative production requirements, when compared to the production of tin and aluminum containers it only uses a fraction of the energy.

Aluminum is a metal that we naturally find on earth and it makes up 8% of earth’s crust. The issue is that Aluminum is always found as an ore, meaning it is found combined with other compounds. To remove aluminum from the other compounds it must be extracted using an extremely energy intensive process. The energy for this process is usually created by burning fossil fuels [2].

When the production process for each is compared it is found that 1 kg of Polyethylene plastics produce around 4 kg CO2 and 1 kg aluminum produces 10.63 kg CO2 [3]. Based solely on the production process plastic appears to be the more environmentally sustainable choice.

Direct Impacts of Packaging Waste in the Environment

Since the 1950’s humans have produced over 9 billion tons of plastic waste that has entered our oceans, rivers, and natural lands. Some of these plastics release chemicals in water and on land that lead to serious health issues like cancer. Additionally, many animals accidently consume plastics, blocking their digestive tracts and leading to their death [4]. Even plants are at risk from plastics. When some plastics breakdown in soil they release chemicals, like Bisphenol A (BPA), that kill natural microorganisms plants need to survive [5].

Since the 1950’s humans have produced over 9 billion tons of plastic waste that has entered our oceans, rivers, and natural lands. Some of these plastics release chemicals in water and on land that lead to serious health issues like cancer. Additionally, many animals accidently consume plastics, blocking their digestive tracts and leading to their death [4]. Even plants are at risk from plastics. When some plastics breakdown in soil they release chemicals, like Bisphenol A (BPA), that kill natural microorganisms plants need to survive [5].

These are just a few of the common issues associated with plastic packaging waste.As we are already aware both of these packaging materials can have negative environmental impacts if not properly disposed of. One of the main concerns for each material is that they take a very long time to degrade in natural conditions. Plastic takes over 400 years to breakdown and tin and aluminum tale 50 – 200 years [8]. Because these materials take so long to degrade more and more of them build up in landfills and ecosystems over time.

That being said, plastic takes over double the amount of time that aluminum and tin do to degrade.

Tinplate and aluminum packaging waste have minimal direct environmental impacts other than utilizing landfill space and being unsightly.

Generally they do not release any harmful chemicals or cause serious harm to plants and animals.

Aluminum and tinplate packaging are clearly the better choice in this regard.

Recycling Packaging Waste

Ultimately, to determine which is the more sustainable form of packaging material we must consider the recycling process for both.

Ultimately, to determine which is the more sustainable form of packaging material we must consider the recycling process for both.

Plastic usage has skyrocketed over the last 50 years, but plastic recycling has barely been able to keep up. Currently only 9% of all plastic is recycled. This is very low when you realize that in the U.S. alone there is over 13 million tons of plastic packaging waste [9].

One of the main hurdles for plastic recycling is that it is difficult. There are multiple types of plastics and they must all be separated and recycled in different ways and at different recycling centers. Furthermore, not all plastic is even capable of being recycled because they contain carcinogens and can release volatile organic compounds if they are melted.

On the other hand tinplate and aluminum are much easier to recycle. They are both metal, so tin and aluminum packaging can be removed from waste flows and landfills using large magnets. Because of this, recycling rates have skyrocketed over the last few years and in 2009 the EU had a recycling rate of 72% for tin and aluminum [6]

When tin and aluminum are recycled it allows for less new metal to be extracted from their ores. This reduces the amount of energy used annually on the production of aluminum and tinplate packaging. Due to this large recycling effort the amount of CO2 created in the production process is only 1/3 of what it would be if new ore were being continually extracted [2].

When the lifecycle of both types of packaging materials are considered it becomes clear that tinplate and aluminum is the more environmentally friendly choice. The world currently has quite a few environmental issues, ranging from stronger weather events to sea level rise. These are global problems that affect all humans, so it is our responsibility to try and combat them. The small daily choices we make have an effect on our future. Even doing something like choosing aluminum packaging helps towards making a sustainable world for our future generations.

References

- [1] http://ec.europa.eu/eurostat/statistics-explained/index.php/Packaging_waste_statistics

- [2] Pongrácz, Eva. (2007). The Environmental Impacts of Packaging. Environmentally Conscious Materials and Chemicals Processing. 237 - 278. 10.1002/9780470168219.ch9.

- [3] Bio Intelligence Service, GHK (2006). Annex 7. A study to examine the benefits of the End of Life Vehicles Directive and the costs and benefits of a revision of the 2015 targets for recycling, re-use and recovery under the ELV Directive. Report prepared for European Commission Environment Directorate-General.

- [4] Plastic waste in the marine environment: A review of sources, occurrence and effects, Science of The Total Environment, Volumes 566–567, 2016, Pages 333-349, ISSN 0048-9697, https://doi.org/10.1016/j.scitotenv.2016.05.084.

- [5] Darcie D Seachrist, Kristen W. Bonk, Shuk-Mei Ho, Gail S. Prins, Ana M. Soto, Ruth A. Keri, Reprod Toxicol. Author manuscript; available in PMC 2017 Jan 1., Published in final edited form as: Reprod Toxicol. 2016 Jan; 59: 167–182. Published online 2015 Oct 19. doi: 10.1016/j.reprotox.2015.09.006

- [6] http://ec.europa.eu/eurostat/statistics-explained/index.php/Packaging_waste_statistics

- [7] http://steelforpackaging.org/pdf/life-cycle-assessment-on-tinplate

- [8] https://www.des.nh.gov/organization/divisions/water/wmb/coastal/trash/documents/marine_debris.pdf

- [9] https://www.thebalancesmb.com/plastic-recycling-facts-and-figures-2877886

{++++}