As online shopping increases, people view products digitally before making a decision to buy. The photographic quality of digital printing which uses the RGB colour model has an important role to play.

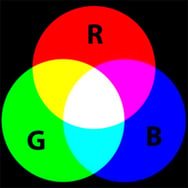

The RGB Colour Model

Digital images are seen in the RGB colour model. These are the colours we view images in cameras, scanners, computer monitors, and CRT/LCD/LED television sets. RGB stands for red, green and blue; the primary colours of light, which when added together give white. This is the reason that RGB is also called the additive colour model. These colours can be expressed only up to 100% intensity when used for printing, but their range is far greater than that of the CMYK colour model. Therefore, RGB can produce lifelike and vibrant colours that the CMYK cannot.

RGB in Printing

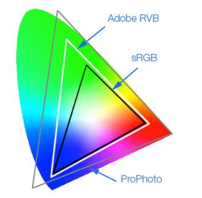

The colour gamut in RGB is the total number of colours it is possible to print. There are many kinds: sRGB (smallest gamut), Adobe RGB (middle gamut), Adobe Wide Gamut RGB, ProPhoto RGB (largest gamut), scRGB, and CIE RGB. The CIE LAB is the colour gamut that a human eye can see, and modern technology so far has not been able to reproduce this range in print. The triangles below show the relation of each print gamut to that of the human eye, which is represented by the horse-shoe shaped spectrum. It is estimated that there are at least 2 million RGB combinations that can be produced for printing.

Image credit: Colour management

RGB printing is done on a black background, which is not possible with CMYK, as black is the colour produced when more colours are added in this colour model. Moreover, RGB prints produce a shimmer and sophistication that is missing in CMYK, and is therefore much sought after by luxury and indulgences products’ manufacturers.

Digital printing

Digital printing of paper has been in use for a long time. Since a few years it is also possible to print metal packages digitally.

Digital printing applies a digital based image directly to the packaging material. There is no need for the intermediary step of making plates with images for the different colours as in offset printing. Professional printing is possible using just small desktop publishing software. It is being used for metals such as aluminium, stainless steel and brass. Laser or inkjet printers are both useful, and inks can be toner or UV.

This method is versatile as it is fast: a large order can be done within a day, creates variable prints, and real-time quality control ensures less wastage.

Advantages of Digital printing

There are many advantages of digital printing over conventional methods like offsetting or flexography.

-

The number 1 advantage is that it is possible to produce small runs of a print without too much cost.

-

Since no image plates are produced it reduces time, and has lower setup costs.

-

Allows for variable data and different images for each impression during printing.

-

Digital printing is considered more environmental friendly to the other methods as it uses less ink, and does not cause as much of air pollution as the other printing methods.

The disadvantage over traditional printing methods is that the cost per print can be expensive, but this is compensated by the high quality of the digital print.

Digital Printing Can Drive Product Sales

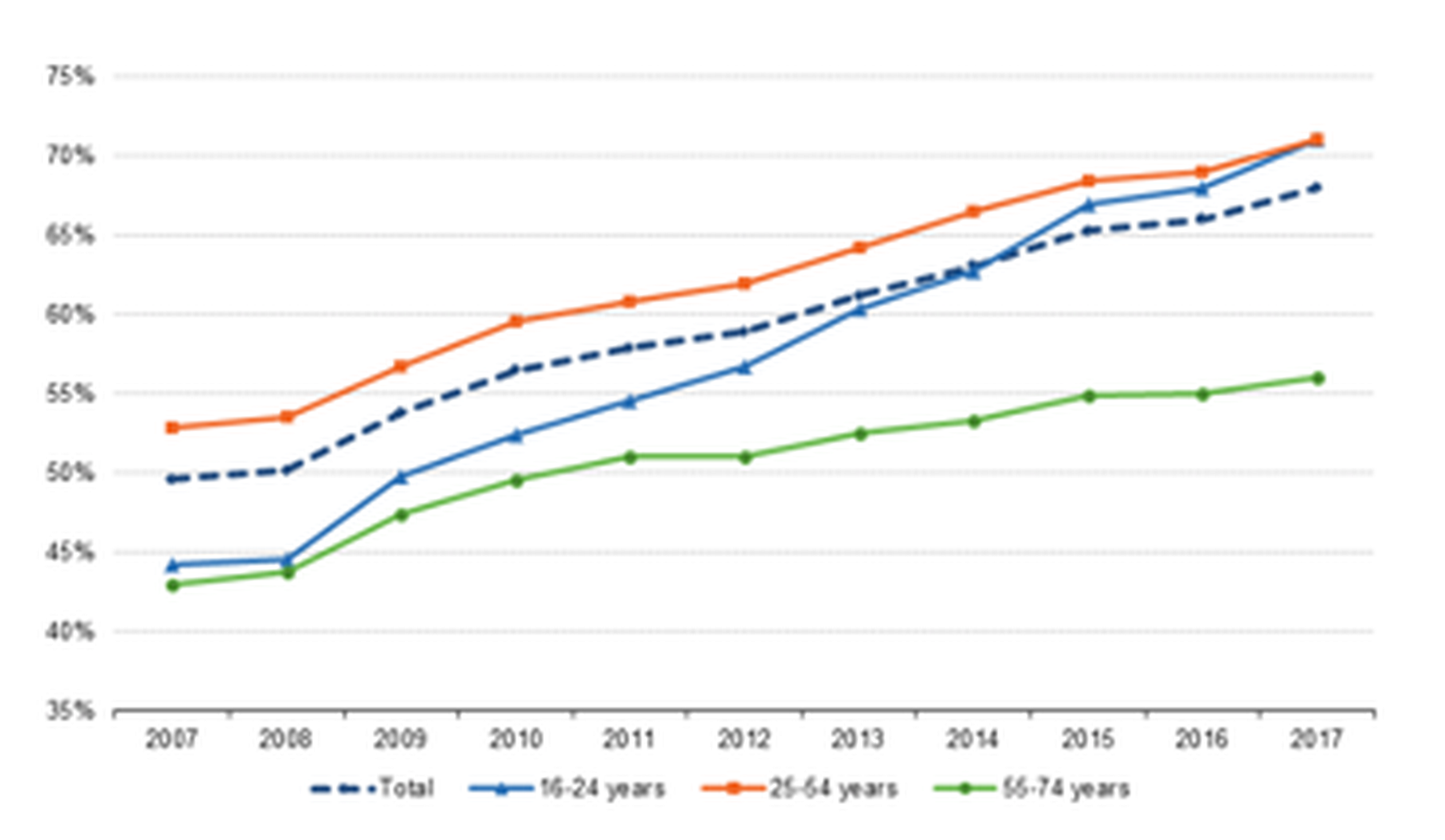

Digital printing fits with the demands and lifestyle of the millennials, who have grown up in the digital era. This group has been driving consumption, and their tastes and preferences matter. In general people are spending increasing amounts of time on the internet; in 2017 they spent nearly 4 hours on the internet each day, an increase of more than 18% in just a year.

In Europe, the millennials and Gen Z were the groups that shopped most often online. Around 70% of internet users in this age segments have purchased online in 2017.

Image credits: Eurostats

Digital images that are more photographic are likely to appeal to them. Moreover, the small runs and individual print possibilities have been used in marketing strategies aimed at the young users. These could be through special promotions or labelling that carry philanthropic messages. For example,

-

A cookie brand, allowed customers to customize their wraps for online orders for a good 40% extra cost.

-

A coffee company ran stories of different farmers and the various social projects financed by the sales proceeds on different packs. This company has been able to increase sales that has gone on to help many farmers by involving coffee consumers by making them feel good.

All these strategies mean more profits.

Future of Digital Printing

In 2015, digital printing on the whole accounted for only 1% in the packaging industry, and 5% of label printing, and together was worth $10.5 billion. By 2020, the share of digital in packaging printing is expected to rise by a CAGR of 13.6%. All this is being been made possible by the RGB colour model.