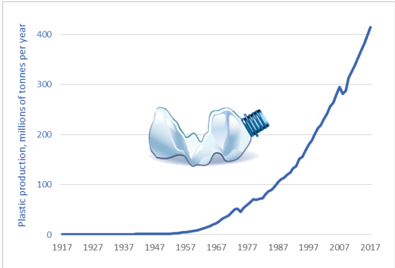

The most commonly used material for packaging is plastic. Plastic is easy to make, but comes with a slew of environmental consequences, like long decomposition rates and damage to natural ecosystems. A great alternative to plastic packaging are metal containers made of tin and aluminum. These containers remove a lot of the issues created by plastic packaging. When metal containers are used for food and other perishables they often still require a plastic film, seal, or coating to completely protect the contents from coming into contact with air. In recent years biodegradable non-plastic packaging and films have begun to immerge as an alternative to standard plastic packaging. Biodegradable packaging is produced using biopolymers, which are molecules often found in living organisms, like cellulose and proteins. This means they can be safely consumed, degrade quickly, and often be created from waste plant products [4].

Forms of Biopolymers

Biopolymers are used to produce a wide variety of biodegradable packaging, from containers with lids to films. In regards to metal containers the 3 most relevant forms of biodegradable packaging used are films, coatings, and bags. Biodegradable films are used to replace polyethylene films. One of the most common uses of these films is wrapping perishables and sealing containers. This makes them one of the most frequently used forms of biopolymers applied in conjunction with metal containers for food and cosmetics. Biodegradable films typically have the same properties as their plastic counterparts, like being water resistant and breathable [2, 3].

Biodegradable coatings are often used on fruits and vegetables to prevent microbial contamination and increase shelf life [1]. They are spread on fruits and vegetables before being packaged or stored in a tin or aluminum container. Biodegradable bags are used to store food and cosmetics within metal containers. These bags are typically strong, flexible, and resistant to temperature or moisture change [4]. This makes them excellent for long term storage or for products that are shipped extended distances.

Biodegradable coatings are often used on fruits and vegetables to prevent microbial contamination and increase shelf life [1]. They are spread on fruits and vegetables before being packaged or stored in a tin or aluminum container. Biodegradable bags are used to store food and cosmetics within metal containers. These bags are typically strong, flexible, and resistant to temperature or moisture change [4]. This makes them excellent for long term storage or for products that are shipped extended distances.

Types of Polymers

Biopolymers used in biodegradable packaging are produced in a few different ways. One of the most common production methods is extracting them directly from plant matter. Starch based packaging is arguably the most common type of biopolymer produced using this method. Green plants, like potatoes, corn, rice, etc., are heated and starch molecules are directly extracted from them. The starch biopolymers are then processed, heated, and turned into a final package shape. Starch is seen as a very good biopolymer because it is produced in mass quantities around the world, 31 billion kg per year, making it very accessible and low cost. Starch based polymers have been proven to successfully replace polystyrene and polyethylene plastics [4].

Another common biopolymer often used in conjunction with starch is chitin. Chitin is commonly found in the skin of insects, cell walls of fungi, and shells of shellfish. Biodegradable films are commonly made with a mix of starch and chitin as they have been shown to have good antimicrobial properties. These films are used in food packaging and as an edible coating for fruits and vegetables [4, 5]. The starch-chitin based coatings work well in conjunction with metal packaging, as they coat perishables and prevent them from coming into contact with air.

Another common biopolymer often used in conjunction with starch is chitin. Chitin is commonly found in the skin of insects, cell walls of fungi, and shells of shellfish. Biodegradable films are commonly made with a mix of starch and chitin as they have been shown to have good antimicrobial properties. These films are used in food packaging and as an edible coating for fruits and vegetables [4, 5]. The starch-chitin based coatings work well in conjunction with metal packaging, as they coat perishables and prevent them from coming into contact with air.

Advantages and Disadvantages

Biodegradable packaging is a very promising alternative to plastic that helps alleviate the long term issues presented by excessive plastic usage. Biodegradable packaging is made of renewable materials, as compared to plastics that are made of oil. In addition, biopolymers are synthesized in a relatively energy efficient process, requiring much less energy than the production of plastic polymers. Another major advantage to biodegradable packaging is that they are not toxic to natural environments or humans. This makes them much easier to dispose of and they do not build up over time like plastics do. Lastly, biopolymers help us reduce our dependence on oil and decrease CO2 emissions. This is arguably the most important advantage to biodegradable packaging, as they work to reduce climate change, which is a worldwide issue [4].

Even though biodegradable packaging is a largely positive thing they are not perfect and do have a few negative qualities. One issue that can arise with the long-term increased usage of biopolymers is that more quantity of plant matter may be required to synthesize biopolymers from. If a more efficient synthetization method is not created within the next 50 years we will need more land to be devoted to agriculture to provide the biomass required to produce all of biopolymers we need. Another issue is that because this is a relatively new process we will need to build many new processing plants to produce these biopolymers [4, 6]. The production of new plants is an expensive, time consuming, and polluting process that will takes many years to complete. Lastly, not all biopolymers can be composted at home and require special composting facilities to be effectively composted [7].

Even though biodegradable packaging is a largely positive thing they are not perfect and do have a few negative qualities. One issue that can arise with the long-term increased usage of biopolymers is that more quantity of plant matter may be required to synthesize biopolymers from. If a more efficient synthetization method is not created within the next 50 years we will need more land to be devoted to agriculture to provide the biomass required to produce all of biopolymers we need. Another issue is that because this is a relatively new process we will need to build many new processing plants to produce these biopolymers [4, 6]. The production of new plants is an expensive, time consuming, and polluting process that will takes many years to complete. Lastly, not all biopolymers can be composted at home and require special composting facilities to be effectively composted [7].

Used in conjunction with metal containers biodegradable packaging is an excellent alternative to common plastic. Biopolymer based films, coatings, and bags protect perishables from coming into contact with microbes and air. They are extracted from natural products and can be produced and disposed of in environmentally sustainable ways. They represent a possible shift away from plastics that can help detach humans from our reliance on fossil fuels.

Learn more about biodegradable and sustainable packaging.

References

- [1] Farrisa S, Schaich KM, Liu LS, Piergiovanni L, Yamab K (2009): Development of polyion-complex hydrogels as an alternative approach for the production of bio-based polymersfor food packaging applications, Trends Food Sci. Technol., 20; 316-332

- [2] Muratore G, Del Nobile MA, Buonocore GG, Lanza CM, Asmundo CN (2005): The influence of using biodegradable packaging films on the quality of decay kinetic of plum tomato, Int. J Food Eng., 67: 393-399

- [3] Sungsuwan J, Rattanapanone N, Rachanapun P (2008): Effect of chitosan cellulose films on microbial and quality discharachteristics of fresh-cut cantaloupe and pineapple. Postharvest Bio. Technol., 49: 403-410.

- [4] Ivonkovic A, Zeljko K, Talic S, Lasic M (2017): Biodegradable packaging in the food industry. Journal of Food Safety and Food Quality., 68: 26-38.

- [5] Zhao Y, Mc Daniel M (2005): Sensory quality of foods associated with edible film and coating systems and shelf-life extension, Innovations in Food Packaging, San Diego, California, Elsevier Ltd., 434-453.

- [6] Aeschelmann F, Carus M (2015): Bio-based building blocks and polymers in the world: capacities, production, and applications. Industrial Biotechnology, 11.

- [7] Wiles DM, Scott G (2006): Polyolefins with controlled environmental degradability, Polymer Degradation and Stability, Volume 91, Issue 7, pp 1581-5192.